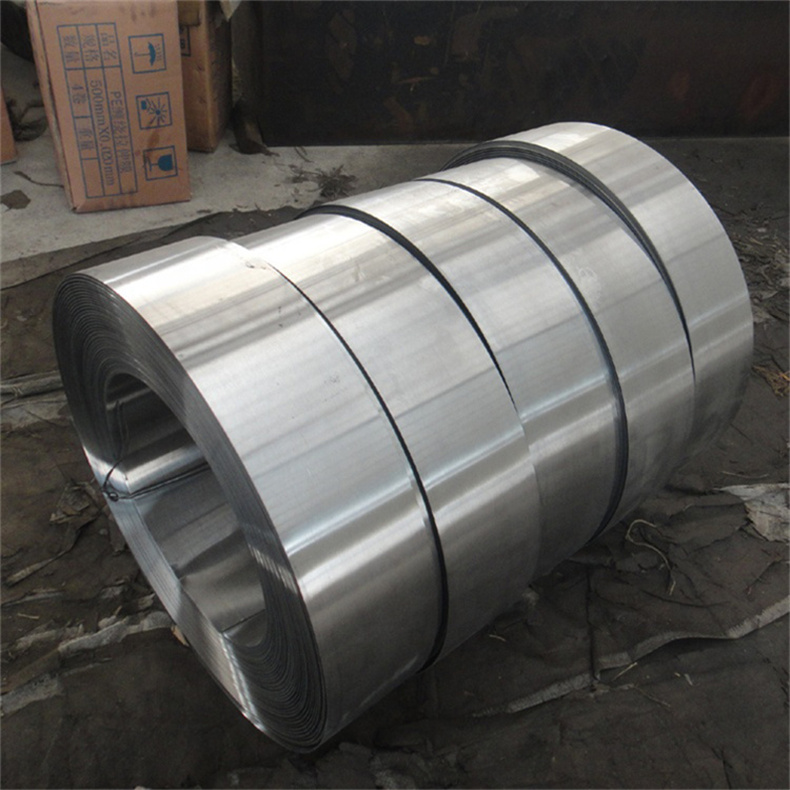

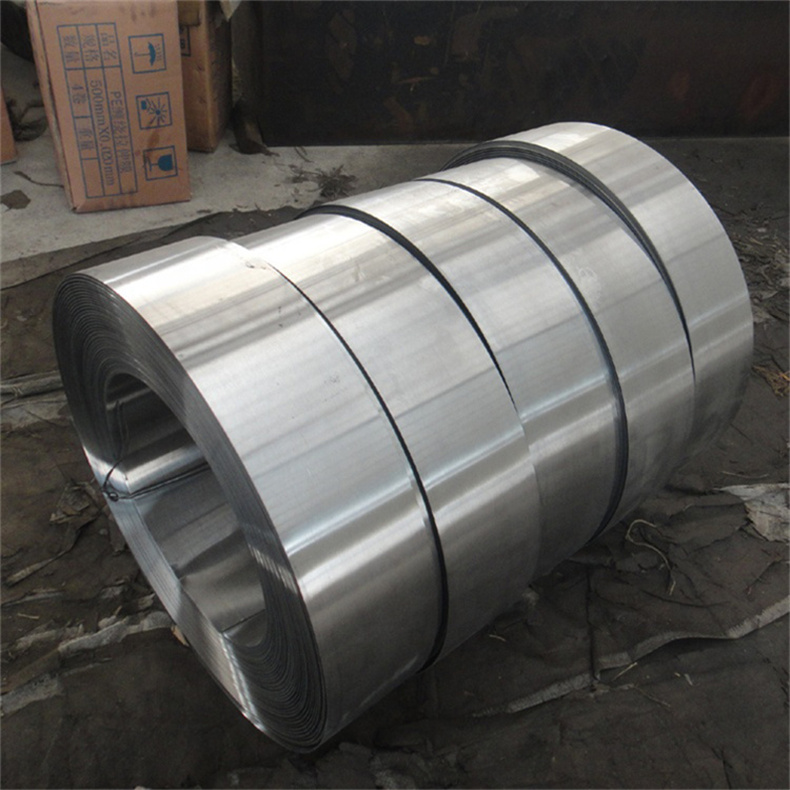

Products

Chemical Composition (%) of 440C Stainless Steel Strip

|

C |

Mn |

Si |

Mo |

Ni |

N |

P |

S |

Cr |

|

0..95-1.20 |

1.00 |

1.00 |

0.75 |

- |

- |

0.040 |

0.030 |

16.00-18.00 |

Mechanical Properties of 440C Stainless Steel Strip

|

Tempering Temperature (°C) |

Tensile Strength (MPa) |

Yield Strength 0.2% Proof (MPa) |

Elongation (% in 50mm) |

Hardness Rockwell (HR C) |

Impact Charpy V (J) |

|

Annealed* |

758 |

448 |

14 |

269HB max# |

- |

|

204 |

2030 |

1900 |

4 |

59 |

9 |

|

260 |

1960 |

1830 |

4 |

57 |

9 |

|

316 |

1860 |

1740 |

4 |

56 |

9 |

|

371 |

1790 |

1660 |

4 |

56 |

9 |

|

* Annealed properties are typical for Condition A of ASTM A276# Brinell Hardness is ASTM A276 specified maximum for annealed 440A, B and C. |

Physical Properties of 440C Stainless Steel Strip

|

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (mm/m/°C) |

Thermal Conductivity(W/m.K) |

Specific Heat

0-100°C (J/kg.K) |

Electrical Resistivity (nW.m) |

|

0-100°C |

0-200°C |

0-600°C |

at 100°C |

at 500°C |

|

7650 |

200 |

10.1 |

10.3 |

11.7 |

24.2 |

- |

460 |

600 |

Stainless steels are high-alloy steels which have high corrosion resistance compared to other steels due to the presence of large amounts of chromium. Based on their crystalline structure, they are divided into three types such as ferritic, austenitic, and martensitic steels. Another group of stainless steels are precipitation-hardened steels. They are a combination of martensitic and austenitic steels.

440C stainless steel is a high carbon martensitic stainless steel. It has high strength, moderate corrosion resistance, and good hardness and wear resistance. Grade 440C is capable of attaining, after heat treatment, the highest strength, hardness and wear resistance of all the stainless alloys. Its very high carbon content is responsible for these characteristics, which make 440C particularly suited to such applications as ball bearings and valve parts.

If you are interested in other Stainless Steel Strip, please click 302, 303, 304, 304L, 304H, 309, 309S, 310, 310S, 310H, 316, 316L, 317/317L, 317LMN, 321, 321H, 330, 347, 347H, 904L, 403, 405, 409, 410, 410S, 410/HT, 416, 416HT, 420, 422, 430, 440C, Duplex 2205, Duplex 2304, Duplex 2507.

Get In touch with