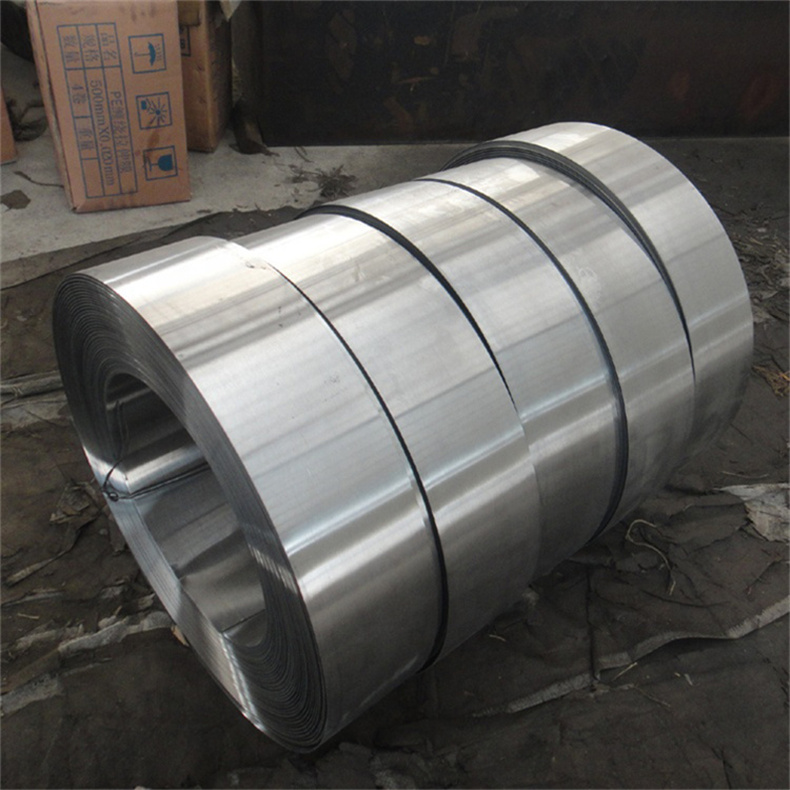

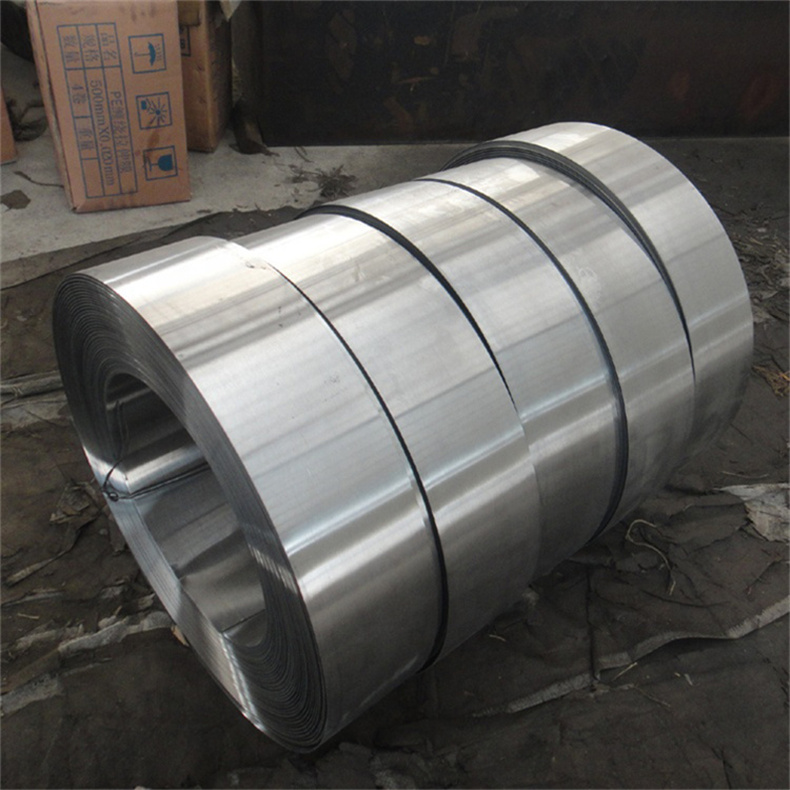

Products

302 is a variations of the 18% chromium / 8% nickel austenitic alloy, which is the most familiar and the most frequently used in the stainless steel family. Alloy 302 is a slightly higher carbon version of 304, often found in strip and wire forms. It is a tough, ductile grade that demonstrates comparable corrosion resistance, is non-magnetic, and is not hardenable by heat treatment. Alloy 302 is usually used in its annealed condition and has a high ease of fabrication and formability.

302 stainless steel is an extremely tough, ductile grade that demonstrates superior corrosion resistance. It is a non-magnetic grade that is not hardenable by heat treating. It is generally used in the annealed condition and is noted for its ease of fabrication and formability.

Although many applications have shifted to 304 and 304L due to advances in melting technology, availability, and cost, Alloy 302 is still used in a variety of industries. Some examples include:

Stamping

Spinning

Wire forming

Formed into all types of washers, springs, screens, and cables

Food and beverage industry

Pressure containing applications

Sanitary or cryogenic applications

Chemical Composition (%) of 302 Stainless Steel Strip

|

Cr |

N |

Mn |

C |

S |

P |

Si |

|

17-19 |

8-10 |

2.00 max |

0.15 max |

0.030 max |

0.045 max |

1.00 max |

Mechanical Properties of 302 Stainless Steel Strip

|

Ultimate Tensile Strength psi |

0.2% Offset Yield Strength psi |

Percent Elongation in 2 inches |

Hardness Rockwell |

|

100,000 |

100,000 |

50 |

B85 |

If you are interested in other Stainless Steel Strips, please click 302, 303, 304, 304L, 304H, 309, 309S, 310, 310S, 310H, 316, 316L, 317/317L, 317LMN, 321, 321H, 330, 347, 347H, 904L, 403, 405, 409, 410, 410S, 410/HT, 416, 416HT, 420, 422, 430, 440C, Duplex 2205, Duplex 2304, Duplex 2507.

Get In touch with